AST2 is an authorized reseller for full range of Artec 3D scanners and software. Our principal customers are Department of Defense agencies, and our customers use Artec scanners for innovation, rapid prototyping and reverse engineering (RE) to support national defense requirements.

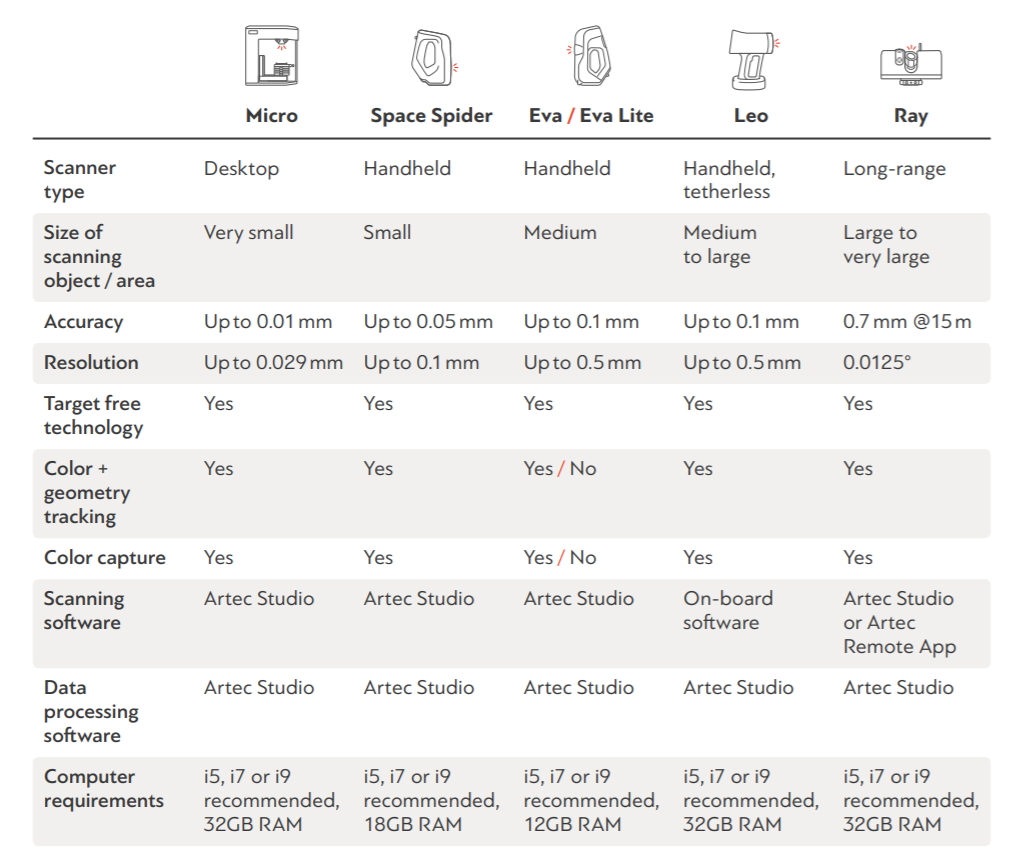

Artec 3D scanners cover full range of scanning requirements:

- Artec Micro, a desktop and fully automated scanner for 3D scanning of small objects with an accuracy of 0.01 mm (10 microns).

- Artec Space Spider, a handheld scanner with high precision (0.05 mm accuracy and 0.1 mm resolution) and versatility, suitable for objects typically about 12 in. in each dimension.

- Artec Eva, a handheld scanner for medium size objects (up to a few feet in any dimension) with an accuracy of 0.1mm and resolution of 0.5 mm. Also available as Artec Eva Lite for entry level applications.

- Artec Leo, a handheld tetherless scanner with built in display suitable for medium to large objects.

- Artec Ray, a long range laser scanner with sub-mm accuracy (0.7 mm at 15 m).

Detailed specification help in identification of the best scanner for individual applications.

Studio software, available for use with Artec (or other) 3D scanners, provides an efficient Scan to CAD tool. Autopilot available with Studio virtually eliminates requirements for alignment and fusion expertise. Recent version, Studio 15, had enhanced features for auto alignment and autopilot.

AST2 integrated Artec scanners into a number of our products and curricula:

- 3D Equipment for Field Logistics Support (3DEFLS), specifically designed as a compact system that can be set-up in 15 minutes for design, scanning and 3D printing.

- Training programs that range from 4 hours to 2 weeks that integrate full range of design, engineering and additive manufacturing (aka 3D printing)

- Pre-apprenticeship and apprenticeship programs

3D Equipment for Field Logistics Support (3DEFLS) are packaged systems that comprise a 3D printer (typically a LulzBot Taz 6, CAD software (SoildWorks or Autodesk, Geomagic), an Artec 3D scanner (Space Spider or Eva) and a workstation. As a package, it offers full capability to design, reverse engineer, and produce rapid prototypes or components for sustainment. All equipment is packaged in a rugged pelican case for easy transportation, use and storage. All equipment can be set-up in less than 15 minutes and be ready to use under field conditions.

Training Programs are offered to help military personnel acquire the skills necessary to design, scan, reverse engineer, and produce rapid prototypes. Hardware used include 3D printers, Artec Space Spider and Eva scanners, and software including SolidWorks, Fusion and Geomagic. Projects are identified for creating innovative solutions during training.

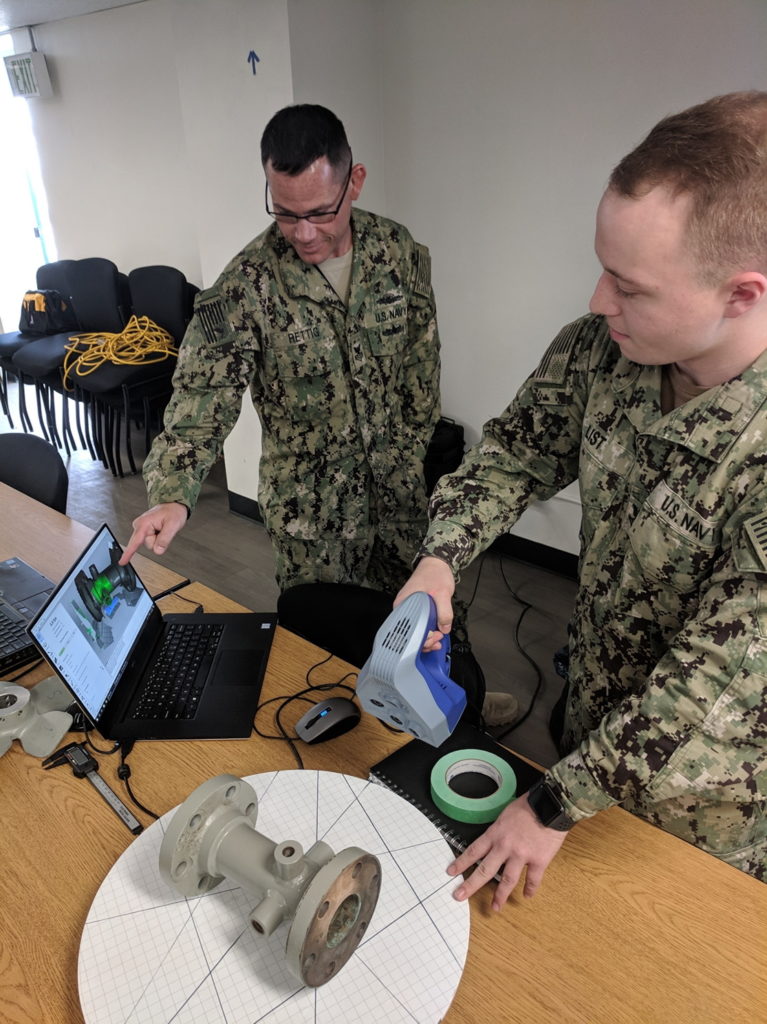

Training Navy at Port Hueneme: We trained Sailors from Naval Surface Warfare Center (NSWC) at Port Hueneme (PHD) during July, 2019. Critical components were scanned using Space Spider, imported into CAD software and produced during training program.

Training Sailors from USS Makin Island: We trained sailors from USS Makin Island and Naval Base San Diego during Feb. 2019. One of the projects was scanned using both Space Spider and Eva, imported into Geomagic to create full design for production.

.